B-4 Odor Control

Receiving and disposing outside grease it is an important aspect of DELCORA’s business. Several upgrades were made to our GAP, including a biological odor control system.

The results: increased convenience for truck drivers, reduced labor for DELCORA operations and maintenance, improved concentrated grease solids, improved odor control, and increased work environment safety.

New Lakeside Raptor Grease Acceptance Plant

This unit screens out large pieces of debris and floating material for disposal without incinerating and which could harm downstream equipment if not removed. Two new grease transfer pumps were also installed—each capable of pumping 400 gallons per minute of up to 8.3% grease at 60 feet.

New grease thickening equipment

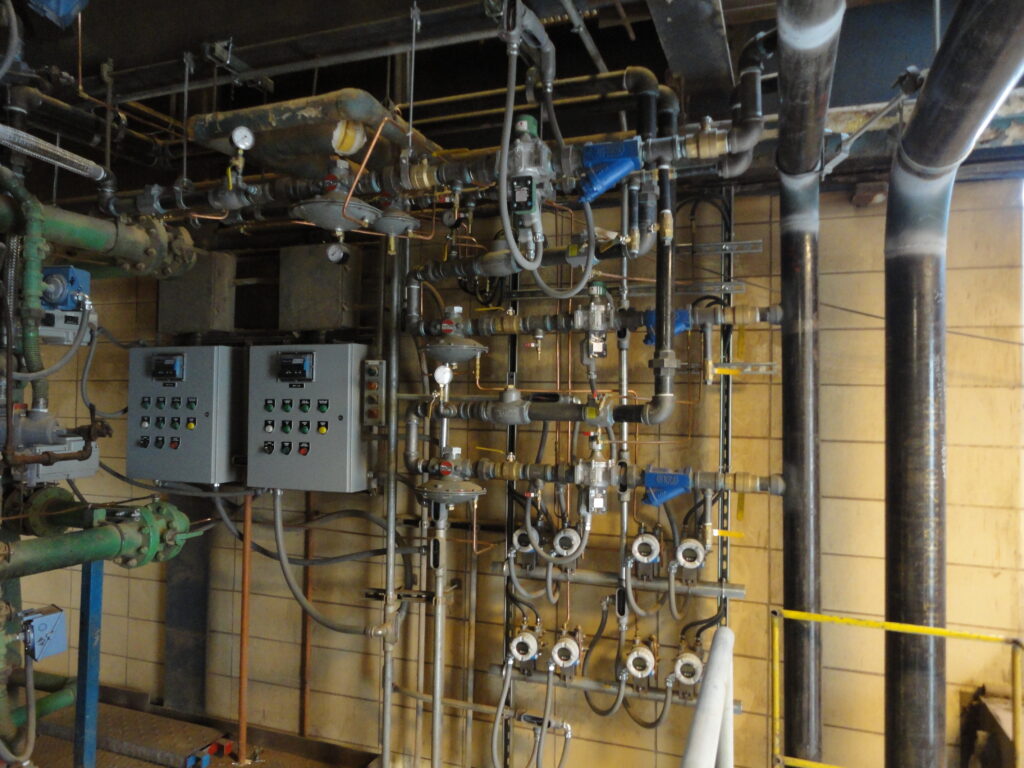

The new equipment included new top skimmers, bottom skimmers, beech section, discharge screw conveyor, and tank cover—for odor control and to keep the building safe. Also included were new control panels for the thickeners, automatic controls for the top and bottom skimmers, and a screw conveyor, as well as emergency back-up equipment.

New BioAir odor control system

The odor control system removes harmful gases including hydrogen sulfide. The new tower is designed to treat 11,500 cubic feet/minute and reduce hydrogen sulfide concentration. This biological packed tower scrubber from BioAir has lower maintenance and a robust biological growth that is able to withstand most upsets.

Other upgrades included a submersible heater and air diffusion system, several natural gas unit heaters, four natural gas instant water heaters, and new gas and fire detectors throughout the building.

implemented a $2.5-million project to modify its two existing 1975 oil-fired sewage sludge incinerators at the Western Regional Treatment Plant (WRTP) with dual-fired burners that are capable of using either natural gas or No. 2 fuel oil. The project involved incinerator modifications, instrumentation and control upgrades, information systems integration and new natural gas utility infrastructure.

implemented a $2.5-million project to modify its two existing 1975 oil-fired sewage sludge incinerators at the Western Regional Treatment Plant (WRTP) with dual-fired burners that are capable of using either natural gas or No. 2 fuel oil. The project involved incinerator modifications, instrumentation and control upgrades, information systems integration and new natural gas utility infrastructure. completed the first milestone in Edgmont Township’s planned implementation of a public sewer system to serve eastern Edgmont. The project involved the installation of a new public wastewater collection system for a community of about 1,000 equivalent dwelling units (EDUs) in the Crum Creek District of eastern Edgmont. The total flow from these users is expected to average 350,000 gallons per day (GPD) of mostly residential wastewater.

completed the first milestone in Edgmont Township’s planned implementation of a public sewer system to serve eastern Edgmont. The project involved the installation of a new public wastewater collection system for a community of about 1,000 equivalent dwelling units (EDUs) in the Crum Creek District of eastern Edgmont. The total flow from these users is expected to average 350,000 gallons per day (GPD) of mostly residential wastewater.